A 级:高风险操作区,如灌装区、胶塞加料盘、敞口的安瓿和西林瓶、无菌对接。通常情况下,该条件下应设有局部单向流保护,例如层流操作台或隔离器。整个 A 级区域的单向流的维护应被证明或验证。应通过设施、设备、工艺及过程的设计来最小化操作人员进入 A 级区的直接干涉活动(例如在没有限制系统和手套箱技术的保护下)的次数。

Grade B area: For aseptic preparation and filling, this is the background cleanroom for the Grade A zone (where it is not an isolator). When transfer holes are used to transfer filled, closed products to an adjacent cleanrooms of a lower grade, airflow visualization studies should demonstrate that air does not ingress from the lower grade cleanrooms to the Grade B. Pressure differentials should be continuously monitored. Cleanrooms of lower grade than Grade B can be considered where isolator technology is used (refer to paragraph 4.22).

B级:对于无菌配制和灌装等高风险操作, B 级区是 A 级洁净区所处的背景洁净室。当使用传递孔来进行传递灌封密闭产品至相邻的低级别房间时,此处的气流流行试验应该证明低级别房间的空气不会倒灌至 B 级别的房间。此处的压差需要连续监测。如果使用了隔离器技术,可以考虑比 B 更低级别(参照条款 4.22)。

Grade C and D area: These are cleanrooms used for carrying out less critical stages in the manufacture of aseptically filled sterile products but can be used for the preparation /filling of terminally sterilized products. (See section 8 for the specific details on terminal sterilization activities).

C级和D级:指用于执行无菌填充产品生产过程不太关键的操作步骤的洁净区, 但可用于制备/灌装最终灭菌产品。(有关最终灭菌活动的详细信息,请参见第 8 节)。

In cleanrooms, all exposed surfaces should be smooth, impervious and unbroken in order to minimize the shedding or accumulation of particulates or micro-organisms and to permit the repeated application of cleaning, disinfectant and sporicidal agents where used.

洁净室内,所有暴露的表面应光滑、无渗漏且无破损以尽可能降低微粒或微生物的脱落或积聚,并可耐受清洗剂、消毒剂和杀孢子剂的重复使用。

在密闭的隔离操作器或手套箱内,可使用单向流或较低的风速。

B级:指无菌配制和灌装等高风险操作A级区所处的背景区域。

C级和D级:指生产无菌药品过程中重要程度较低的洁净操作区。

洁净室和区域内的气流流形应进行可视化研究,以证明从低等级区域到较高等级区域没有倒灌,并且空气不会从较不洁净的区域(例如地板)或经过操作员或设备将污染传递至高级别的区域。其他需要证明气流流型的区域应通过风险评估来进行。气流流型的研究应在动态和静态条件下进行。记录气流流型的视频应保存。当建立设施的环境监测计划时,应考虑气流可视化研究的结果。

气闸的设计和使用应能提供物理隔离以最大限度地降低不同区域的微生物和微粒污染,并为物料和人员在不同级别之间的移动提供通道。如果可能,用于人流的气闸间应当与用于物流的气闸间分开。如果不能实现,应该考虑按时间分别执行人流、物流的程序。气闸应能被经过滤的空气有效地吹扫来确保洁净级别的维持。气闸的最后阶段在静态状态下应与其通向的洁净室的洁净度相同(活性和非活性颗粒)。进入和离开 B 级洁净室的更衣室期望独立设置。在不可行的情况下,应考虑按程序将活动(进/出)基于时间的分隔。如果 CCS(污染控制策略) 指出交叉污染的风险很高,则应考虑进入和离开生产区域的单独更衣室。气闸的设计应如下:

Personnel airlocks: Areas of increasing cleanliness used for entry of personnel (e.g. from Grade D to Grade C to Grade B). In general hand washing facilities should be provided only in the first stage of the changing room and not be present in changing rooms directly accessing Grade B cleanrooms.

人流气闸室:人员进入更高级别洁净度的区域(例如,从D 级到 C 级到 B 级)。通常来讲,洗手设施只能在更衣室的第一阶段提供, 并且直接进入 B 级别的更衣室不能有洗手设施。

Material airlocks: used for materials and equipment transfer.Only materials and equipment that have been included on an approved list, developed during validation of the transfer process, should be allowed to be transferred into the Grade A zone or Grade B cleanroom via an airlock or pass-through hatch. Equipment and materials (intended for use in the Grade A zone) should be protected when transiting through the Grade B cleanroom. Any unapproved items that require transfer should be pre-approved as an exception. Appropriate risk assessment and mitigation measures should be applied and recorded as per the manufacturer’s CCS and should include a specific disinfection and monitoring programme approved by quality assurance.

物流气闸:用于物料和设备的传递,只有包含在确认列表部分中并且经过传递验证的的物料和设备方可通过气锁或通道转移进 A/B 级区域;当在 A级区使用的设备、 物料从 B 级区转移时, 应该被保护起来。任何未经批准的物料需要转移都属于需要预先批准的异常情况。应根据生产商污染控制策略进行适当的风险评估和降低措施,并予以记录,应包含由质量保证部门批准的特定的消毒和监测程序。

Pass-through hatches should be designed to protect the higher grade environment, for example by effective flushing with an active filtered air supply.The movement of material or equipment from lower grade or unclassified area to higher grade clean areas should be subject to cleaning and disinfection commensurate with the risk and in line with the CCS.

传递窗的设计应能保护较高等级的环境,例如通过使用主动过滤的空气进行有效风淋。将物料从低级别或未定级区域移至更高等级的洁净区域时,应进行与其风险相称清洁和消毒并符合 CCS(污染控制策略)。

Both sets of doors for pass-throughs and airlocks (for material and personnel) should not be opened simultaneously. For airlocks leading to a Grade A zone and Grade B areas, an interlocking system should be used. For airlocks leading to Grade C and D cleanrooms, a visual and/or audible warning system should be operated as a minimum. Where required to maintain zone segregation, a time delay between the closing and opening of interlocked doors should be established.

气闸和传递窗两端的门不得被同时打开。通向 A 级区和 B 级区的气闸应使用互锁系统,并能防止有超过一扇的门被同时打开;对于通向 C 级区与 D 级区的互锁,应至少有一个可视和/或可听的报警系统运行。当需要维持区域隔离时,应建立互锁门开关时间的延迟(即互锁门关闭只有需要隔一段时间才能重新打开)。

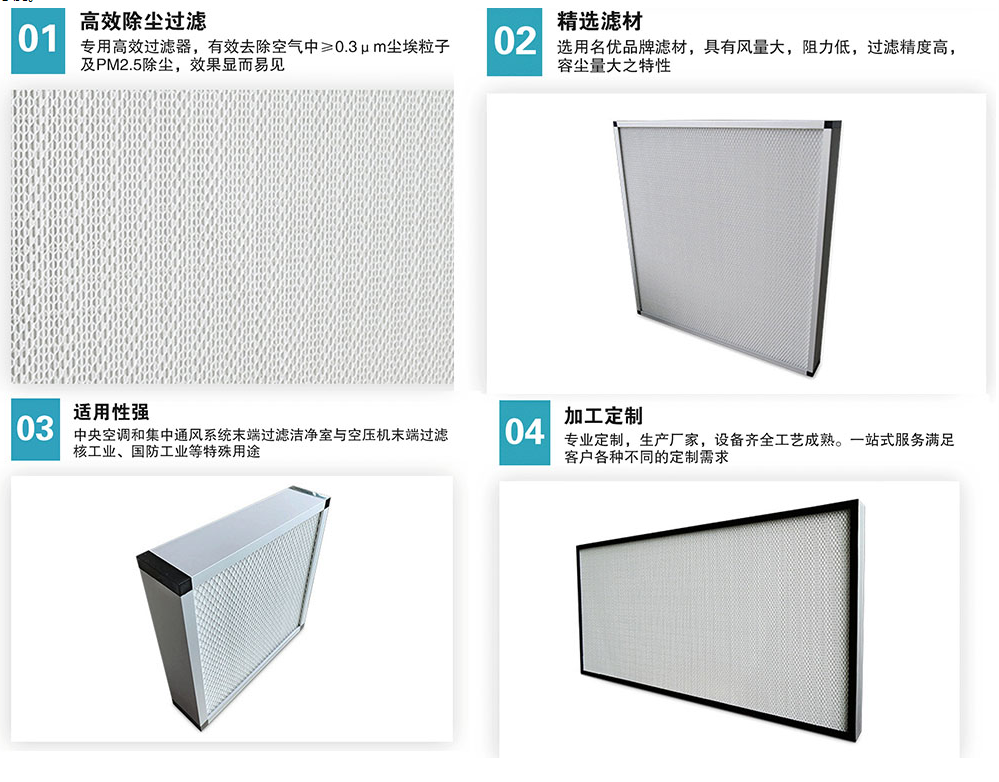

Cleanrooms should be supplied with a filtered air supply that maintains a positive pressure and/or an airflow relative to the background environment of a lower grade under all operational conditions and should flush the area effectively. Adjacent rooms of different grades should have pressure differentials of a minimum of 10 pascals (guidance value). Particular attention should be paid to the protection of the critical zone. The recommendations regarding air supplies and pressures may need to be modified where it is necessary to contain certain materials (e.g. pathogenic, highly toxic or radioactive products or live viral or bacterial materials). The modification may include positively or negatively pressurized airlocks that prevent the hazardous material from contaminating surrounding areas. Decontamination of facilities (e.g. the cleanrooms and the heating, ventilation, and air conditioning (HVAC) systems) and the treatment of air leaving a clean area, may be necessary for some operations. Where containment requires air to flow into a critical zone, the source of the air should be from an area of the same grade.

洁净室应提供经过过滤的空气,该空气供应在所有操作条件下均相对于较低等级的背景环境保持正压和/或气流, 并能有效冲洗该区域。不同洁净级别的相邻房间之间应维持至少 10 帕(指导值)的压差。应特别注意对风险级别最高的区域的保护,如包括一些物料, 如致病性的、高毒性、放射性或活病毒或细菌物料或产品,与送风和压差相关的建议可能需要调整, 调整可包括正压或负压气闸,以防止有害物质污染周围区域。设施净化,如洁净室和空调系统,以及在某些操作时对排出洁净区的空气的处理可能是有必要的。如果防止外泄需要空气流入关键区域,则空气来源应来自相同等级的区域。

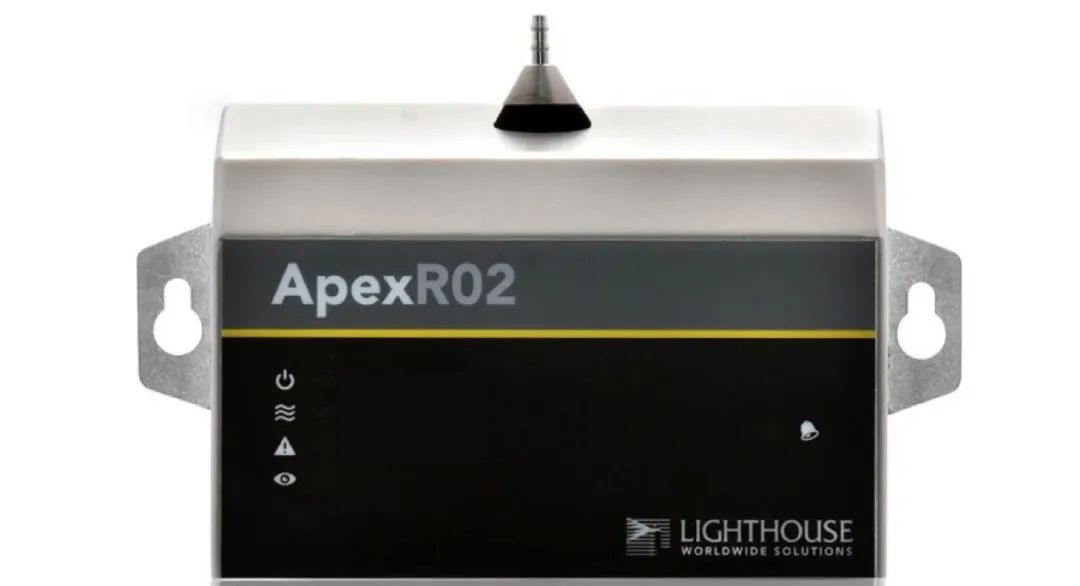

Indicators of pressure differences should be fitted between cleanrooms and/or isolators. Set-points and the criticality of pressure differentials should be documented within the CCS. Pressure differentials identified as critical should be continuously monitored and recorded. A warning system should be in place to instantly indicate and warn operators of any failure in the air supply or reduction of pressure differentials (below set limits for those identified as critical). The warning signal should not be overridden without assessment and a procedure should be available to outline the steps to be taken when a warning signal is given. Where alarm delays are set, these should be assessed and justified within the CCS. Other pressure differentials should be monitored and recorded at regular intervals.

洁净室和/或隔离器之间应安装压差指示器。设定点和压差的临界值应在 CCS(污染控制策略)文件化。被确定为关键压差的应得到连续监测和记录。应建立警告系统以便立即向操作员指示并警告气体供应出现任何故障或压差降低(低于确定为关键的限度值)。未经评估,不得摒弃报警信号,并且应提供程序概述发出警告信号时应采取的步骤。如果设置了警报延迟,则应在 CCS 内对其进行评估和证明。其他压力差应定期监测和记录。

气锁间两侧的门不应同时打开。可采用连锁系统或光学或(和)声学的报警系统防止两侧的门同时打开。

在任何运行状态下,洁净区通过适当的送风应能确保对周围低级别区的正压,维持良好的气流组织,保证有效的净化能力。

当使用或生产某些致病性、剧毒、放射性、活病毒、活细菌的物料或产品时,空调净化系统的送风和压差应作适当调整以防止有害物质外溢。必要时,生产操作的设备及该区域的排风应作去污染处理(如排风口安装过滤器)

应设送风机组故障的报警系统。应在压差十分重要的相邻级别区之间安装压差表。压差数据应定期记录或者归入有关文挡中。

用于无菌工艺的 RABS 或开放隔离器的关键区域应满足 A 级区单向气流要求。在气流可能不是单向的封闭式隔离器系统中,应提供 A 级条件,并应证明在加工过程中为暴露的产品提供足够的保护。RABS 和开放隔离器的设计,应保证气流从关键区域流向周边区域(除非需要控制外泄,在这种情况下需要局部抽气以防止污染物转移到周围的房间)。负压隔离室应仅在必须对产品进行隔离的时候使用, 并采取风险控制措施以确保关键区域不受损害。

For RABS used for aseptic processing, the background environment should meet at least Grade B. The background environment for open isolators should meet Grade C or D, based on a risk assessment. Airflow studies should be performed to demonstrate the absence of air ingress during interventions, such as door openings.

对于 RABS,背景环境应满足 B 级区要求,根据风险评估,开放隔离器的背景环境应达到C 级或 D 级。应当进行气流研究,以证明在干预过程中(例如门打开)没有空气进入。

The background environment of a closed isolator should correspond to a minimum of Grade D. The disinfection/decontamination programme should be included as a key consideration when performing the risk assessment for the CCS of an isolator. Where additional process risks are identified, a higher grade of background should be considered. The decision as to the supporting background environment should be documented in the CCS.

封闭式隔离器的背景环境应至少达到 D 级。在进行隔离器 CCS 风险评估时,应将消毒/净化程序作为关键考虑因素。如果确定了其他过程风险,则应考虑更高级别的背景。有关背景环境的决定应记录在 CCS中 。

物品进出隔离操作器应特别注意防止污染。

隔离操作器所处环境的级别取决于其设计及应用。无菌生产的隔离操作器所处环境的级别至少应为D级。

第十五条 隔离操作器只有经过适当的验证后方可投入使用。验证时应当考虑隔离技术的所有关键因素,如隔离系统内部和外部所处环境的空气质量、隔离操作器的消毒、传递操作以及隔离系统的完整性。

第十六条 隔离操作器和隔离用袖管或手套系统应进行常规监测,包括经常进行必要的检漏试验。