很多行业会使用无尘室,只要是小颗粒会对生产过程产生不利影响的地方都会有洁净室的身影。它们的尺寸和复杂度各不相同,广泛应用于半导体制造,制药,生物技术,医疗设备和生命科学等行业,以及航空航天,光学,军事和能源部中常见的关键工艺制造。

对于用于无菌产品生产的洁净室和洁净空气设备,需要按照GMP相关法规要求,去进行定期检测或验证,确保适当的洁净度水平,今天中邦兴业小编,跟大家分享一下关于无菌产品生产的洁净室和洁净空气设备验证标准及要求。

Cleanrooms and clean air equipment such as unidirectional airflow units (UDAFs), RABS and isolators, used for the manufacture of sterile products, should be qualified according to the required characteristics of the environment. Each manufacturing operation requires an appropriate environmental cleanliness level in the operational state in order to minimize the risk of contamination of the product or materials being handled. Appropriate cleanliness levels in the “at rest” and “operational” states should be maintained.

用于无菌产品生产的洁净室和洁净空气设备,如单向流单元(UDAF)、RABS 和隔离器,应根据所要求的环境特性进行确认。每个生产操作都要求在动态条件下达到适当的环境洁净度水平,最大程度降低所处理的产品或物料的污染风险。应维持“静态”和“动态”下的适当洁净度水平。

Cleanrooms and clean air equipment should be qualified using methodology in accordance with the requirement. Cleanroom qualification (including classification) should be clearly differentiated from operational environmental monitoring.

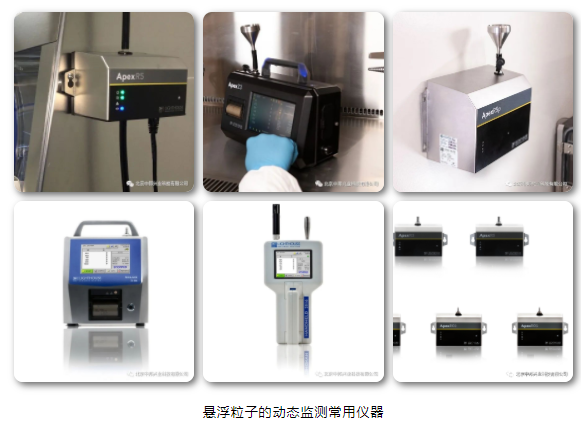

应使用符合要求的方法对洁净室和洁净空气设备进行确认。洁净室确认(包括分级)应与动态环境监测明确区别开来。

Cleanroom and clean air equipment qualification is the overall process of assessing the level of compliance of a classified cleanroom or clean air equipment with its intended use. As part of the qualification requirements, the qualification of cleanrooms and clean air equipment should include (where relevant to the design/operation of the installation):

洁净室和洁净空气设备的确认是评估分级的洁净室或洁净空气设备与其预期用途的符合程度的整体过程。作为的确认要求的一部分,洁净室和洁净空气设备的确认应包括(与设施的设计/运行相关的):

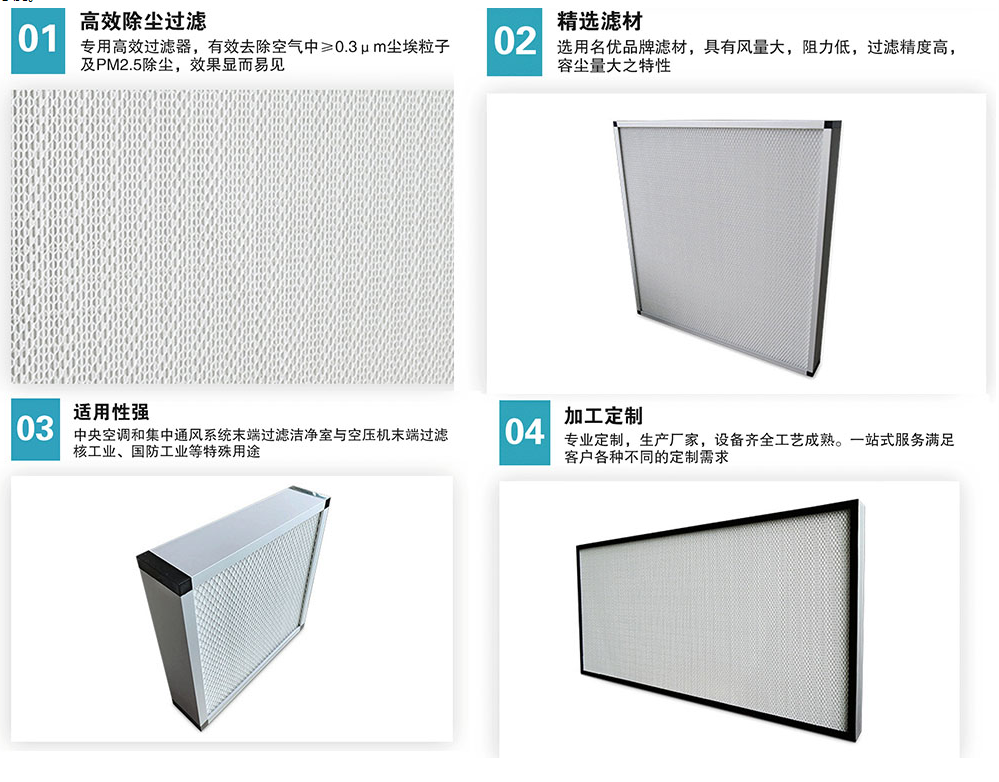

- Installed filter system leakage and integrity testing. 已安装的过滤器系统的检漏和完整性测试。

高效过滤器检漏主要是现场检漏,通过DOP法来发现滤器本身及运输、安装过程中可能存在的问题。常使用气溶胶光度计及多分散气溶胶进行检漏。依据的标准是2010药品GMP指南(测试方法采用ISO14644-3)。

- Airflow tests – volume and velocity. 气流测试——体积和流速。

- Air pressure difference test. 压差测试。

- Airflow direction test and visualization.气流方向测试和可视化。

气流流型测试的目的,是观察在工作区域里面气流的运动模式,同时也可以观察仪器设备对气流的影响。气流流型测试应该在气流的风速与均匀度都测试完毕且通过之后进行,过早进行可能得不到正确的数据。一般而言气流流型的测试,是由肉眼观察所决定。使用的工具包括烟雾、水雾、 PFA 、和轻质棉线。烟雾或水雾的共同优点是只要粒子够小,烟雾可随风飘扬,可正确的反映气流运动模式。可持续大量的发雾,可以实现长时间观测,且不会污染洁净室环境,满足法规要求的可视化烟雾试验要求,是目前采用最多的测试方法。 - Microbial airborne and surface contamination. 浮游菌和表面污染

GMP附录一 无菌药品第十一条 应当对微生物进行动态监测,评估无菌生产的微生物状况。监测方法有沉降菌法、定量空气浮游菌采样法和表面取样法(如棉签擦拭法和接触碟法)等。动态取样应当避免对洁净区造成不良影响。成品批记录的审核应当包括环境监测的结果。对表面和操作人员的监测,应当在关键操作完成后进行。在正常的生产操作监测外,可在系统验证、清洁或消毒等操作完成后增加微生物监测。

- Temperature measurement test. 温度测定测试。

- Relative humidity test. 相对湿度测试。

- Recovery test. 自净测试。

- Containment leak test. 容器检漏测试。

Reference for the qualification of the cleanrooms and clean air equipment can be found in the ISO 14644 series of standards.

洁净室和洁净空气设备的确认可参考 ISO 14644 系列标准。

Cleanroom classification is part of the cleanroom qualification and is a method of assessing the level of air cleanliness against a specification for a cleanroom or clean air equipment by measuring the total particle concentration. Classification activities should be scheduled and performed in order to avoid any impact on process or product quality. For example, initial classification should be performed during simulated operations and reclassification performed during simulated operations or during aseptic process simulation (APS).

洁净室分级是洁净室确认的一部分,是一种根据洁净室或洁净空气设备的标准通过测定总微粒浓度来评估空气洁净度水平的方法。分级活动的安排和执行,应避免对工艺或产品质量产生任何影响。例如,应在模拟操作期间进行初步分级,在模拟操作或无菌工艺模拟试验(APS)期间进行再分级。

For cleanroom classification, the total of particles equal to or greater than 0.5 and 5 μm should be measured. This measurement should be performed both at rest and in simulated operations in accordance with the limits specified.

对于洁净室分级,应测定等于或大于0.5μm 和 5μm 的微粒总数。应按照规定的限度,在静态和模拟操作中进行测定。

- Classification including 5μm particles may be considered where indicated by the CCS or historical trends. 在 CCS 或历史趋势中有说明的情况下,可以考虑包括 5μm 微粒的分级。

- For grade D, in operation limits are not predetermined. The manufacturer should establish in operation limits based on a risk assessment and routine data where applicable. 对于 D 级区,没有预先确定的动态限度。生产商应根据风险评估和适用的常规数据建立动态限度。

For classification of the cleanroom, the minimum number of sampling locations and their positioning can be found in ISO 14644 Part 1. For the aseptic processing area and the background environment (the grade A and grade B areas, respectively), additional sample locations should be considered and all critical processing areas such as the point of fill and container closure feeder bowls should be evaluated. Critical processing locations should be determined by documented risk assessment and knowledge of the process and operations to be performed in the area.

对于洁净室的分级,采样点的最小数量及其位置可参见 ISO 14644 第 1 部分。对于无菌工艺区及其环境(分别为 A 级和 B 级区),应考虑额外的釆样位置,并应评估所有关键操作区,例如灌装点和包材进料斗。关键操作位点应通过有书面的风险评估以及对该区域所进行的工艺和操作的了解来确定。

Cleanroom classification should be carried out in the “at rest” and “in operation” states.

洁净室分级应在“静态”和“动态”下进行。

- i. The definition of “at rest” state is the condition whereby the installation of all the utilities is complete including any functioning HVAC, with the main manufacturing equipment installed as specified but not operating and without personnel present in the room. “静态”是指所有公用设施(包括任何正常运行的 HVAC)已安装完成、主生产设备按规定安装但未运行、并且无人员在场的状态。

- ii. The definition of “in operation” state is the condition where the installation of the cleanroom is complete, the HVAC system fully operational, equipment installed and functioning in the manufacturer’s defined operating mode with the maximum number of personnel present performing or simulating routine operational work.

“动态”是指洁净室安装完成、HVAC 系统全面运行、设备已安装并按照生产商规定的运行模式运行、并且有最大数量的操作人员在场执行或模拟日常操作的状态。

- iii. The total particle limits given above for the “at rest” state should be achieved after a “clean up” period on completion of operations and line clearance/cleaning activities. The “clean up” period (guidance value of less than 20 minutes) should be determined during the qualification of the rooms, documented and adhered to in procedures to reinstate a qualified state of cleanliness if disrupted during operation.

应在操作和生产线清场/清洁活动完成后的“自净期”达到给出的“静态”总微粒限度。“自净期”(指导值小于 20 分钟)应在房间确认过程中确定,在程序中进行记录并遵守,以便在操作过程中洁净度受到损坏的情况下,将房间恢复到经确认的洁净状态。

The speed of air supplied by unidirectional airflow systems should be clearly justified in the qualification protocol including the location for air speed measurement. Air speed should be designed, measured and maintained to ensure that appropriate unidirectional air movement provides protection of the product and open components at the working position (e.g. where high-risk operations occur and where product and/or components are exposed). Unidirectional airflow systems should provide a homogeneous air speed in a range of 0.36 – 0.54 m/s (guidance value) at the working position, unless otherwise scientifically justified in the CCS. Airflow visualization studies should correlate with the air speed measurement.

单向流系统送风速度的合理性应在确认方案中明确论证,包括风速的测定位置。风速的设计、测定和维持应确保在工作区域(例如,在进行高风险操作的区域以及产品和/或组分暴露的区域)有合适的单向气流为产品和开放组件提供保护。除非在 CCS 中另有科学论证,否则单向流系统应在工作区域提供 0.36-0.54m/s(指导值)的均匀风速。气流可视化研究应与风速测定相关联。

The microbial contamination level of the cleanrooms should be determined as part of the cleanroom qualification. The number of sampling locations should be based on a documented risk assessment and the results obtained from room classification, air visualization studies and knowledge of the process and operations to be performed in the area. The maximum limits for microbial contamination during qualification for each grade are given. Qualification should include both “at rest” and “in operation” states.

洁净室的微生物污染水平应作为洁净室确认的一部分进行确定。采样点的数量应基于书面的风险评估、房间分级结果、气流可视化研究以及对该区域要进行的工艺和操作的了解。给出了各级别确认过程中的微生物污染最大限度。确认包含“静态”和“动态”条件中。

(a) Settle plates should be exposed for the duration of operations and changed as required after a maximum of 4 hours. Exposure time should be based on recovery studies and should not allow desiccation of the media used.

沉降碟应在操作期间暴露,并在最多 4 小时后按需要更换。暴露时间应基于回收率研究,并且避免所所用培养基干燥。

All methods indicated for a specific grade in the table should be used for qualifying the area of that specific grade. If one of the methods tabulated is not used, or alternative methods are used, the approach taken should be appropriately justified.

指示表中具体级别的所有方法应用于该级别区域的确认。如果不釆用表格中的某种方法,或使用替代方法,应进行适当论证。

Limits are applied using CFU throughout the document. If different or new technologies are used that present results in a manner different from CFU, the manufacturer should scientifically justify the limits applied and where possible correlate them to CFU.

在整个文件中使用 CFU 表示限度。如果采用不同的或新的技术并且结果不以 CFU 的方式呈现,生产商应科学地论证其限度,并尽可能将其与 CFU 相关联。

- For the qualification of personnel gowning, the limits given for contact plates and glove prints should apply.对于人员更衣的确认,应采用表面微生物和五指手套的限度要求。

- Sampling methods should not pose a risk of contamination to the manufacturing operations.釆样方法不应给生产操作带来污染风险。

The requalification of cleanrooms and clean air equipment should be carried out periodically following defined procedures. The requalification should include at a minimum the following:

洁净室和洁净空气设备的再确认应按照规定的程序定期执行。再确认应至少包括以下内容:

- – Cleanroom classification (total particle concentration). 洁净室分级(总微粒浓度)。

- – Integrity test of final filters. 最终过滤器的完整性测试。

- – Airflow volume measurement. 气流量测定。

- – Verification of air pressure difference between rooms. 房间之间的压差确认。

- – Air velocity test (Note: For grade B, C and D the air velocity test should be performed according to a risk assessment documented as part of the CCS. However, it is required for filling zones supplied with unidirectional airflow (e.g. when filling terminally sterilized products or background to grade A and RABS). For grades with non-unidirectional airflow, a measurement of recovery testing should replace velocity testing). 风速测试(注:对于 B 级、C 级和 D 级,风速测试应按照风险评估的结果进行,并将该风险评估包含到CCS 中。但是,使用单向流的灌装区(例如,灌装最终灭菌产品时或 A 级和 RABS 的背景区)需要进行测试。对于非单向流的级别,应以自净测试代替风速测试)。

The maximum time interval for requalification of grade A & B areas, is 6 months. A 级和 B 级区再确认的最长时间间隔为 6 个月。

The maximum time interval for requalification of grade C & D areas, is 12 months. C 级和 D 级区再确认的最长时间间隔为 12 个月。

Appropriate requalification consisting of at least the above tests should also be carried out following completion of remedial action implemented to rectify an out of compliance equipment or facility condition or after changes to equipment, facility or processes as appropriate. The significance of a change should be determined through the change management process. Examples of changes to be considered include but are not limited to the following:

在纠正设备或设施缺陷而采取的整改措施完成后,或设备、设施或工艺的变更后,还应视情况进行上述检测进行适当的再确认。变更的重要性应通过变更管理程序确定。需要考虑的变更案例包括但不限于:

- i. Interruption of air movement which affects the operation of the installation. 气流中断,影响装置的运行。

- ii. Change in the design of the cleanroom or of the operational setting parameters of the HVAC system.洁净室设计或 HVAC 系统的操作设定参数的变更。

- iii. Special maintenance which affects the operation of the installation (e.g. change of final filters). 影响装置操作的特殊维护(例如最终过滤器的更换)。

北京中邦兴业作为一家高端洁净产业全方位解决方案服务商,可以根据客户需求,为客户提供洁净室环境验证仪器设备及检测验证服务,如果您有洁净室环境监测、验证方面的问题,可随时与我们联系,技术工程师随时帮您解答。