| Mode

模式 |

Phase

阶段 |

Action

行动 |

| At Rest

空态/静态 |

Filter Face to Critical Operation

从过滤器面到关键操作位 |

Intended to capture unidirectional airflow under “At-Rest” conditions over critical areas where components and open product are located during the manufacturing process

旨在捕获制造过程中组件和开放产品所在关键区域的“静止”条件下的单向气流 |

| Perimeter (Ingress)

四周(入口) |

Intended to capture the airflow at the barrier interface between the unidirectional airflow or Grade A air supply areas and their background areas and at defined openings in isolators.

用于捕获单向气流或 A 级供气区域与其背景区域之间的屏障接口处以及隔离器中定义开口处的气流。 |

|

| In Operation

运行中 |

Setup

开启 |

Intended to capture unidirectional airflow over the equipment setup activities for manufacturing where personnel are setting up the equipment

旨在捕获设备开启时的活动上的单向气流,以便在人员开启设备进行制造时更好地应对 |

| Filter Face to Critical Operation

从过滤器面到关键操作位 |

Intended to capture unidirectional airflow over the product path including over critical areas where components and open products are located during the manufacturing process

旨在捕获产品路径上的单向气流,包括在制造过程中组件和开放产品所在的关键区域的气流流型 |

|

| Interventions

干预 |

Intended to capture airflow over critical areas where personnel intervene during in process intervention

旨在捕获人员在过程干预过程中干预的关键区域的气流 |

All smoke studies shall be performed during normal operating conditions.

所有气流流型测试应在正常运行条件下进行。

Smoke may be introduced perpendicular to or opposite to the airflow direction,however it is recommended that smoke is introduced perpendicularly

气流流型测试的烟雾可以垂直于或相反于气流方向引入,建议垂直引入烟雾比较好。

While performing smoke studies “At-Rest” or “In-operation” notes shall be taken to identify anomalies and document activities performed in the filling room. Any interruption in the video recording shall be documented.

在进行气流流型测试时,应记录“静止状态”或“运行中状态”记录,以识别异常并记录在灌装室中进行的活动。视频录制中的任何中断均应记录在案

GB50073-2013

GB50472-2008

GB 50346-2011

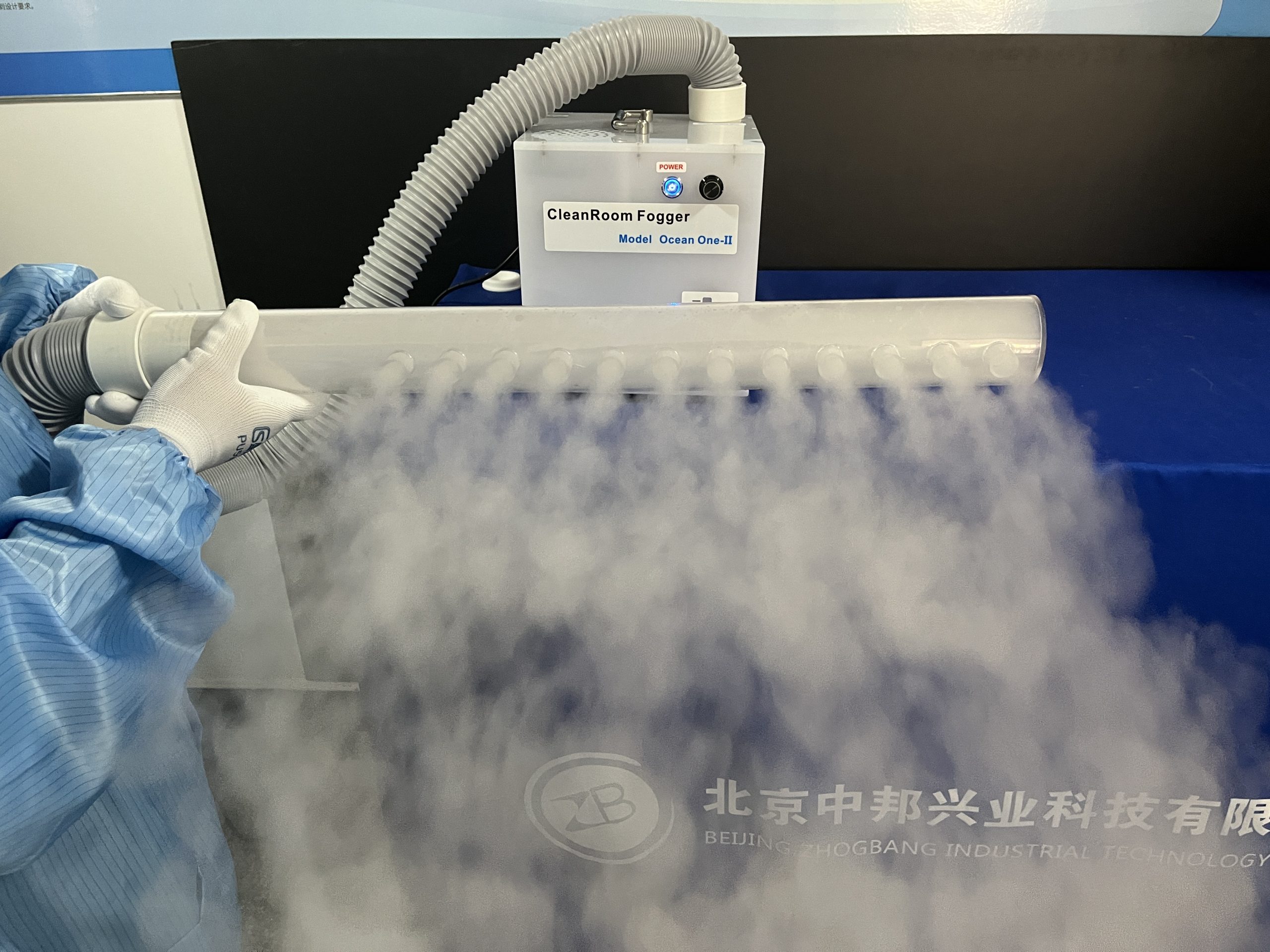

北京中邦兴业自主研发的气流流型检测仪所使用的耗材为去离子水或纯水,因此其产生的烟雾,无毒无污染并且从源头上确保了完全无残留,因为粒径较小烟雾静态留存时间长。

广泛应用于微电子、医疗制药、生化制品、食品卫生、精密机械、精细化工和航天航空等多个领域。

【气流流型检测仪发雾效果】

这款烟雾发生器是纯水烟雾发生器,它可以发出高浓度的水蒸气,这些水蒸气的粒径范围是1—10um,集中度达到了80%以上,因此高度可见,具有很高的视觉性,又毫无污染,因为水蒸气在洁净室内散发之后,没有任何残留物质会留在洁净室内。

气流流形测试仪利用超声雾化的原理,将DI水雾化成0.3-5 微米左右的大量水滴,建立一个气溶胶,由风扇吹出,可以显示出洁净室气流组织状态,发现湍流。因为颗粒更小、悬浮性更好并且视觉效果很白,风量可调节,目测效果更明显,拍摄效果更清晰,可以达到更好的气流拍摄效果。

- Airflow shall be outward from the critical zone气流应从高级别区向外

- No airflow shall enter the critical zone没有气流进入高级别区

Each“In-Operation” smoke study shall capture airflow over the critical product areas and shall include the following:

每次“动态”气流流型测试应捕获关键产品区域的气流,并应包括以下内容:

A personnel present and performing normal production activities

A级区操作人员在场并执行正常的生产活动;

Personnel from Sterility Quality Assurance shall be present to verify acceptable airflow patterns during “In-Operation” Testing

在“动态”测试期间,无菌质量保证部门的人员应到场验证可接受的气流模式;

The effects of disturbances

测试异常情况如干扰的影响

Airflow recovery back to smooth unidirectional airflow

气流回流到层流罩的单向气流

Smoke generation shall not alter the actual airflow currents

烟雾发生器(测试设备)对实际气流不产生影响。

The following minimum acceptance criteria shall be met

应满足以下最低验收标准:

- During intervention activities, smoke shall move down and away from the product

- 在干预活动期间,烟雾应向下移动并远离产品

- The airflow shall not move over the operator and then toward the critical area

- 气流不得越过操作人员,然后流向关键区域

- When there is a disruption in the airflow, recovery shall happen quickly to establish unidirectional flow. It may be necessary to show that smoke in the area of the intervention does not enter into the adjacent zones that are not cleared.当气流中断时,应迅速恢复以建立单向流动。

- 可能有必要证明干预区域的烟雾不会进入未清除的相邻区域。

- Airflows smoothly in one direction without eddies or turbulences prior to contacting any surfaces to ensure sterile product, containers, and closures are only exposed to first air.

- 空气在接触任何表面之前沿一个方向平稳流动,没有涡流或湍流,以确保无菌产品,容器和瓶盖仅暴露在第一次空气中。

- Noingress of air from the areas outside the curtain/barrier door

- 没有空气从窗帘/屏障门外的区域进入